Microscope Incubation Systems (Zeiss)

Microscope Heaters offers a range of incubation systems from a variety of platforms such as: -Zeiss Microscope Incubation Systems -Leica Microscope Incubation Systems -Olympus Microscope Incubation Systems -Nikon Microscope Incubation Systems -Andor, Crest, Witec & Abberior Microscope Incubation Systems Based at the University of Sussex, Microscope Heaters have been designing and supplying systems such as microscope incubation chambers and stage top incubator heaters into the research microscopy community for nearly two decades. Helping to keep cells alive and providing live cell imaging. Featuring: -CO2 Gas Controllers -Vibration Free Heaters -Stage Top Incubation -High Resolution Microscopes -Microscope Cooling and Heating Stage -Microscope Environmental Chambers with Temperature Control

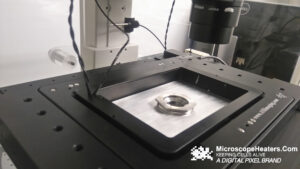

Microscope Stage Top Incubation & Incubators

Stage Top Incubator Systems All heated inserts & stage top incubation systems include independent temperature control over the insert and the glass top of the insert, and are sealed to maintain gas control. Combination systems are available with CO2 and CO2 - O2 controllers. Systems normally accept a 3mm OD flexible tube for gas delivery- other options are available. Microscope Incubation Chamber Designed for applications such as patch clamp or perfusion studies where access to the sample is essential, this system boasts a dual temperature control configuration. It controls the temperature of the heated insert, and optionally controls the temperature of media entering the sample area. Intravital Microscopy Imaging System Designed for whole animal viability during extended imaging experiments the system boasts two independent temperature control channels. The first controls a heated insert, the second a heated blanket. Combined with a third independent temperature monitoring system, this solution has been shown time and time again to provide the best results. Compatible with a wide range of motorised microscopes, this system is used on many two-photon experimental systems. A removable insert in the heating assembly, and titanium windows completes the system solution.

(Carbon Dioxide) CO2 Gas Controllers

Carbon Dioxide CO2 Gas Controller Systems A wide variety of cell systems, require a closely controlled CO2 concentration to maintain cell viability over extended periods. While it is possible to use 5% CO2 cylinders, these are expensive, bulky and provide limited flexibility in terms of the CO2 concentration range possible. Put simply 5% CO2 concentration at the cylinder does not guarantee the optimum outcome for your cells. Furthermore the use of flow based mixing systems, while a little less expensive provide far from consistent gas concentrations. Microscope Heaters CO2 gas controllers only require 100% CO2. Additional gas supplies such as air or N2 are not necessary. DP 2000 CO 2 STD Designed to meet the CO2 requirements of a single microscope system, it features a long life internal pump. The Flow Rate is continuously variable, with a CO2 concentration range is 0.1-18%. DP 2000 CO2 O2 SINGLE Designed for hypoxia studies, this system measures CO2 and O2 concentration within the sample area. Microprocessor based technology maintains CO2 concentration in the range 0-8% range is 0.1-20% and O2 concentration in the range 21% to 1.0%. Direct measurement in the sample area provides clear and obvious benefits over measuring gas concentrations at a distance. Features: High Performance NIRD CO2 detector used to monitor concentration. Long life pump provides excellent gas delivery. Microprocessor controlled concentration levels - No Guess work. Only 100% CO2 gas supply required for full operation- No O2 or N2 required. Sealed Inserts As part of our gas controller range we have also designed a range of sealed inserts for industry standard motorised stages. Normal inserts are open and as a result cannot maintain when a desired CO2 concentration in the sample area.

Vibration Free Heaters

Vibration Free Incubation Our vibration free heater systems provide the ultimate in system thermal homogeneity and stability. Is Vibration Free Operation Really So Important? Is Vibration Free Operation Really So Important? Well an increasing number of scientists think so. Their experiments really demand it. For more demanding techniques, such as Super Resolution Microscopy, electrophysiology, tweezer experiments or simply using a x60 or x100 objective- the removal of this complication has obvious advantages! On the other hand, in any kind of microscopy, it is really one less thing to worry about with numerous side benefits. Better Focus Stability Most fan based systems warm the sample area by blowing warm air into the environmental incubation system- once the system detects a drop in temperature. This method is a second order control mechanism relying on the system making an educated guess as to the power requirements of the heater, and then has to factor in the rate of air flow in the system. This leads to well documented oscillations in the temperature at the sample, which can result in reduced cell viability as well as increased focus drift. Microscope Heaters Heaters, on the other hand, gently warm the sample area from both sides and as a result reach a steady state equilibrium with a steady flow of heat into the sample area. The result better microscope stability- less focus drift! How can I be sure that the temperature across my 96 well dish is constant? The only way that we can think of is by gently warming the sample area from both sides, across the width of the sample area. Microscope Heaters achieve this by using multiple heaters. In tests, the temperature measured from one edge of a typical 96 or 24 well dish is constant to within the accuracy of a P100 sensor! If you blow hot air across a sample area- the physics of the situation lead to thermal gradients across the sample area. Wider Temperature Range- Is it Important? Most Microscope Heater systems can only provide any thermal accuracy when the required temperature is 4-6oC above the ambient temperature. There is a minimum amount of heat that they can put into the system. Microscope Heaters Heater systems confidently cope with anything from 1oC above ambient to up to 50oC depending on the system configuration. This allows a wider range of samples to be studied- especially important when you have invested heavily in the latest microscope technology. Especially important for Core Facilities. Reliability Really Is Important! Microscope Heaters Heater Systems have no moving parts- no fans to break down - no air filters to replace. As a result, our new Gen II systems have in excess of 80 equipment years in the field without a systems failure - not one has broken down! This means much less down time on your time lapse system.

Want to know more?

Do you wish to reach out for more information or see how we can help you? Reach out to us by clicking the button below!